Laser beam shapers are optical components which change input beams to create certain radiance patterns in the output beam. The need for such elements stems from the fact that there are many situations in which the original radiance pattern of the laser beam is suboptimal for a given application.

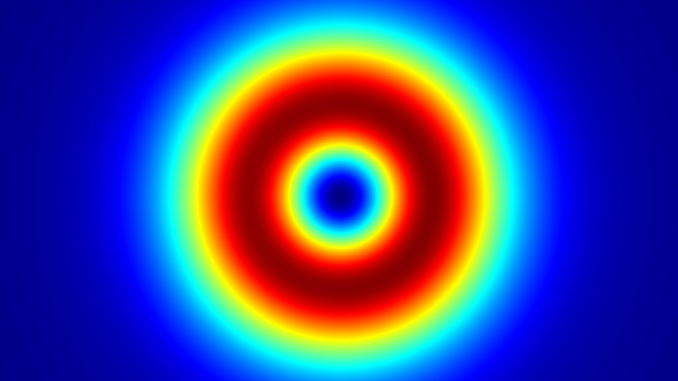

The most common scenario is one in which the input beam has a Gaussian radiance profile, and the user needs to change it to something that is less smooth with sharper edges. Gaussian beams are very smooth and, when in focus, are not well bound. Thus, some percentage of light is always landing outside the intended area of the focus spot. In contrast, a beam with a radiance resembling a Top Hat beam is very well confined and uniform. A laser beam shaper can be used to transform a Gaussian beam into such a Flat Top beam.

The application from above is only one example of what a laser beam shaper can accomplish. The laser beam shaper can be used to alter the shape of the input beam in many more ways, not just flat top energy distributions. For instance, it can be used to obtain specific geometrical shapes or even more complex patterns, such as isolated areas or parallel lines, to name a few.

There are two main types of laser beam shapers. They are:

· Diffractive beam shapers.

· Refractive beam shapers.

Diffractive beam shapers work by taking advantage of the wave nature of light. Thus, the design of this type of laser beam shaper considers interference effects. Refractive beam shapers, on the other hand, work simply according to the laws dictated by geometrical optics. In other words, their design assumes that light can be solely treated as rays that bend their direction when they change medium.

When choosing a laser beam shaper, one must consider the characteristics of the laser in question and the desired shaping. If the laser is single mode, and the desired shape is small (i.e., a few times the size of the focused spot without the shaper), then diffractive beam shapers are the best solution, as they have absolute shaping accuracy enabling stability of the shape even when it is small. This is often the case in industrial laser beam shaping for precise micro machining applications.

If the laser is single mode, but the desired shape is large, a refractive beam shaper is better as they tend to have good uniformity even for large shapes. This is often the case for applications such as large area heating/ annealing or inspection and medical sensing.

Be the first to comment