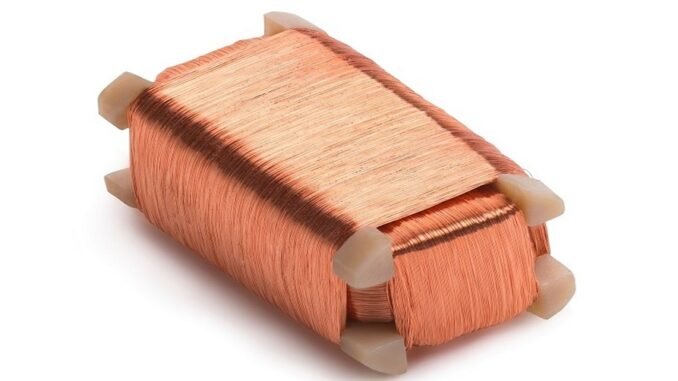

The advancement in the medical technology has been quite promising. With the growth of non invasive technologies, it is becoming important that the device sizes are getting smaller in order to accommodate for the smaller devices, hence the micro coil technology is very high in demand. The micro coil winding is done in such a way that the device size becomes small enough to be accommodated within the human body. The micro coil manufacturing process is quite challenging considering the complexity of the size and the material. Moreover, the thickness of the coil also poses new challenges that make micro-coil manufacturing truly a learning curve.

In this article, we’ll delve deeper into the micro coil manufacturing process and how it has improved the efficiency of the medical devices. Moreover, we will also try to find out some of the applications of the medical devices in the non invasive medical treatments.

So let us get started.

Challenges with traditional micro coil winding

The micro coil winding deals with coils which have thickness lower than that of human hair. Integration becomes quite challenging under such scenarios. Integrating it with the micro coil miniature devices would require the traditional soldiering method. These methods often result in the following problems:

- Melting of the micro coil as a result of higher temperature.

- Oxidation of the micro coil thus resulting in change of the chemical properties.

- Alteration with the physical properties of the MIC required, thus making them unfit for medical use.

Medical applications are one of the most profound reasons for the micro coil to be implemented. Since the medical applications have a high risk involved, the quality of the coil along with the hygiene becomes quite important. It is for this reason that a new technology of thermal pressure bonding has been introduced for the integration.

Thermo Pressure Bonding – A Micro Coil Winding Technology for Smarter Devices

Coping up with the technological limitations has been quite challenging when it comes to micro coil. The thermal pressure bonding has been a lifesaver. Making the integration quite possible without bringing about any changes in the physical or chemical properties of the wire is what makes this process seamless.

In order to implement thermal pressure bonding, we must keep the following points in mind:

- Both the wires should be of similar material

- The thickness of both the wires should be similar.

- Both thickness and the wire material should be the same.

Applications of micro coil in the medical device industry.

The size of the medical devices is becoming miniaturized overtime. What this means is that the growth of non-invasive surgery is also increasing.

Here are some of the applications of the micro coil medical devices:

- Targeted delivery of drugs during the chemotherapy session is possible with the micro-devices

- Simulations of the brain impulses and monitoring them are possible due to miniaturized devices.

- Precise positioning of the stent and radiation catheters has been made possible due to the micro coil led devices.

- Physiological and flow related data can be monitored – which fall under the ambiance of diagnostic applications.

Be the first to comment